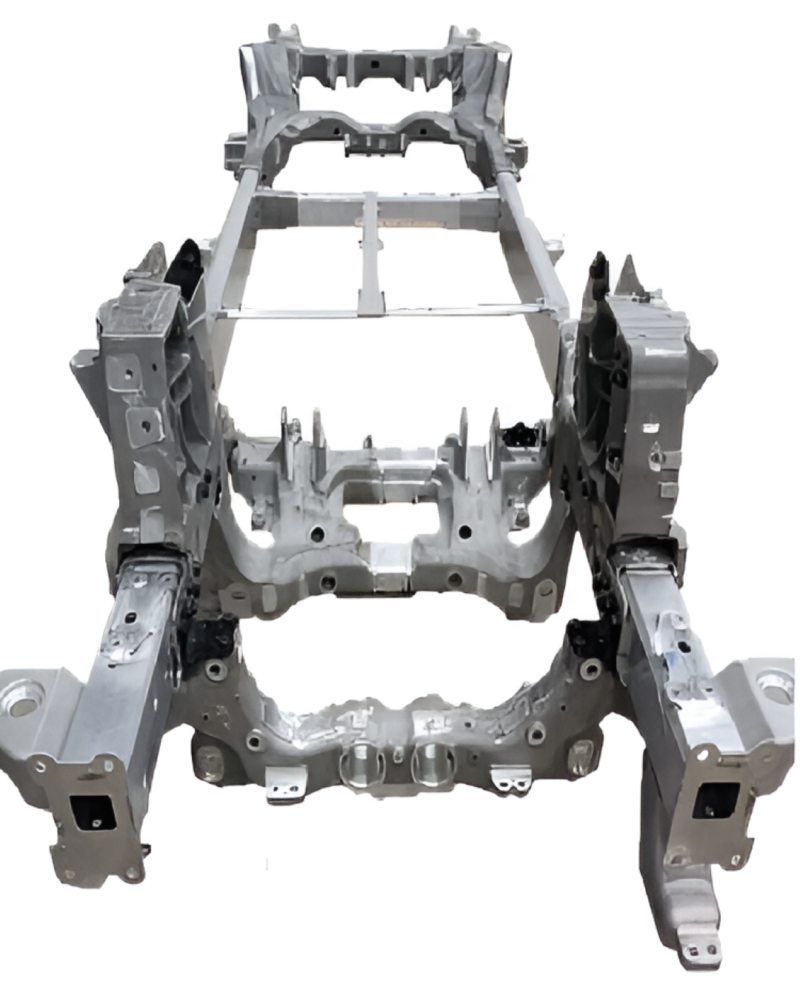

BYD Yangwang U8L Debuts World's First Single-Piece Aluminum Automotive Chassis Frame

Hubei Hantek Equipment Manufacturing Co. have unveiled the world's first one-piece, low-pressure-cast aluminum frame for large vehicles at the 2025 Yangtze River Industry and Technology Innovation Conference. The showpiece frame is the ladder rail chassis of the BYD Yangwang U8L, a high-end electric SUV that launched in September 2025.

The frame covers an area of 4.2 square meters with wall thickness ranging from 4mm to 50mm—a thickness ratio exceeding 12:1.

No prior global project has successfully cast a frame with such extreme thickness variation.

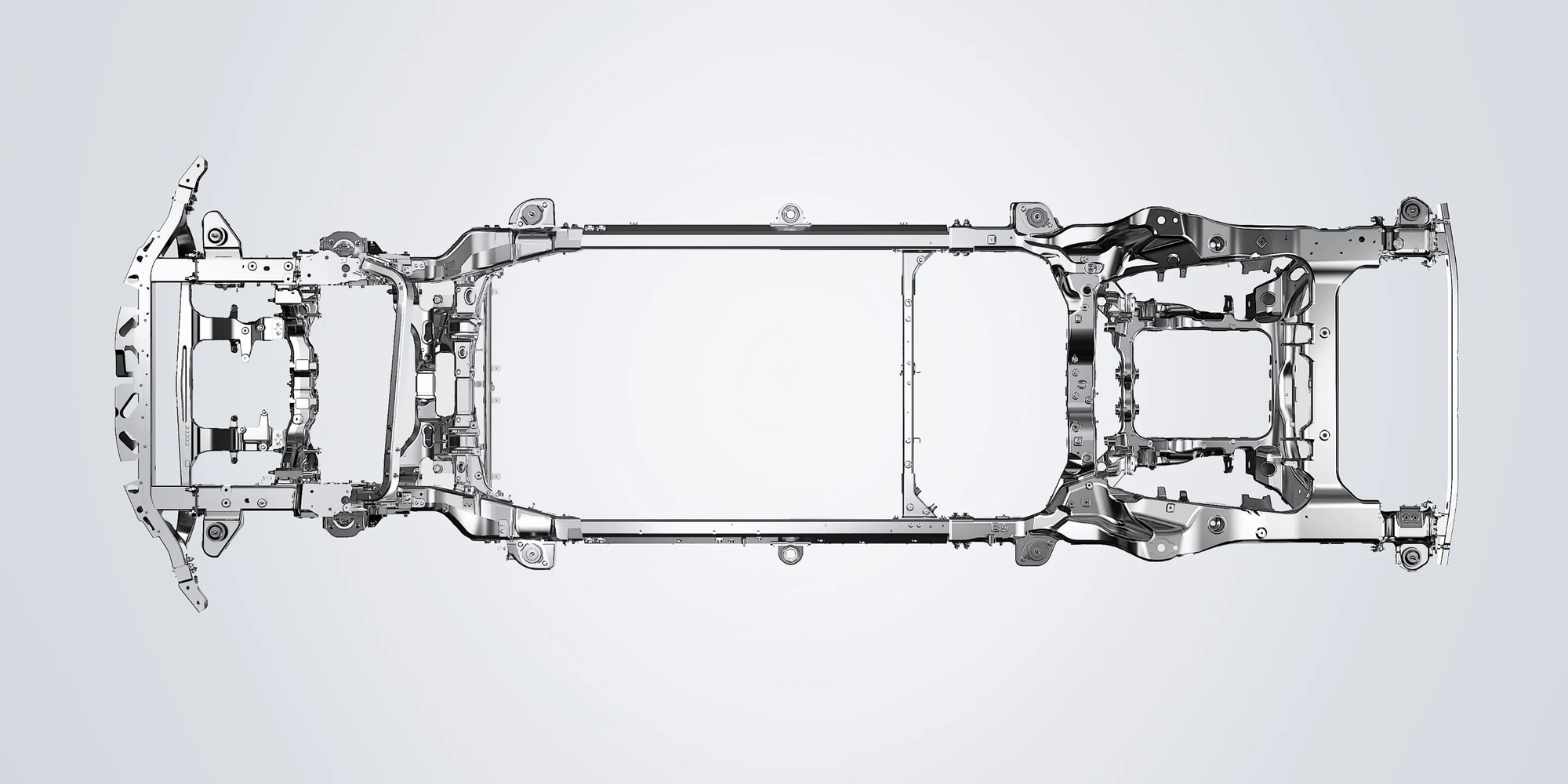

The Manufacturing Constraint That Shaped Vehicle Architecture

Traditional chassis frames are constructed from numerous individual pieces connected via welding or alternative fastening techniques. This introduces both technical complexity and elevated manufacturing costs when compared to a one piece construction.

Joints become structural weak points.

During vehicle operation, these connection points face torsional loads (twisting), bending loads (flexing), and vibrational forces from the engine, road, and aerodynamics. The result shows up in real-world performance as poor handling and cornering stability, unpredictable suspension response, premature component wear, and diminished safety.

Hantek's single-piece design will help address these issues and even change how these vulnerabilities react in real world applications.

What This Technical Milestone Reveals

The achievement marks a visible shift in Chinese automotive manufacturing capability. A decade ago, Chinese auto manufacturing was perceived as inferior. Today, manufacturers are leading new technical innovations.

China produced nearly 30% of the world's vehicles in 2024, making it the largest automotive manufacturer—more than double the output of the USA. The country is also the world's largest exporter of vehicles.

This production scale creates the manufacturing ecosystem necessary to support advanced processes like Hantek's low-pressure casting technology.

Structural Benefits of Integrated Design

The integrated frame design improves overall body rigidity and torsional stiffness. Optimized force flow through the structure enhances crash protection.

Hantek highlighted that its aluminum alloy material and heat treatment provide a balance of high strength, toughness, and fatigue resistance.

During BYD's extreme testing, the maximum impact energy reached 50.4 kJ (approximately 37,200 lb-ft). After three consecutive drops, the Yangwang U8L body structure remained intact, doors still opened, and columns didn't bend.

Supply Chain Implications

Hantek has established partnerships with other automakers in addition to BYD, including the likes of Nio, FAW Hongqi, and Dongfeng.

This existing supplier network suggests the single-piece casting approach will likely be adopted by other manufacturers who may develop their own vehicles built on similar one-piece chassis frame designs.

The one piece frame methodology has potential to reshape how large-vehicle frames are engineered and manufactured throughout the automotive sector, and marks a critical breakthrough in China's ability to produce oversized, intricate aluminum structural elements.

SOURCE: https://www.ithome.com/0/902/455.htm

SOURCE: https://carnewschina.com/2025/12/04/worlds-first-one-piece-cast-aluminium-vehicle-frame-revealed-on-byd-yangwang-u8l/